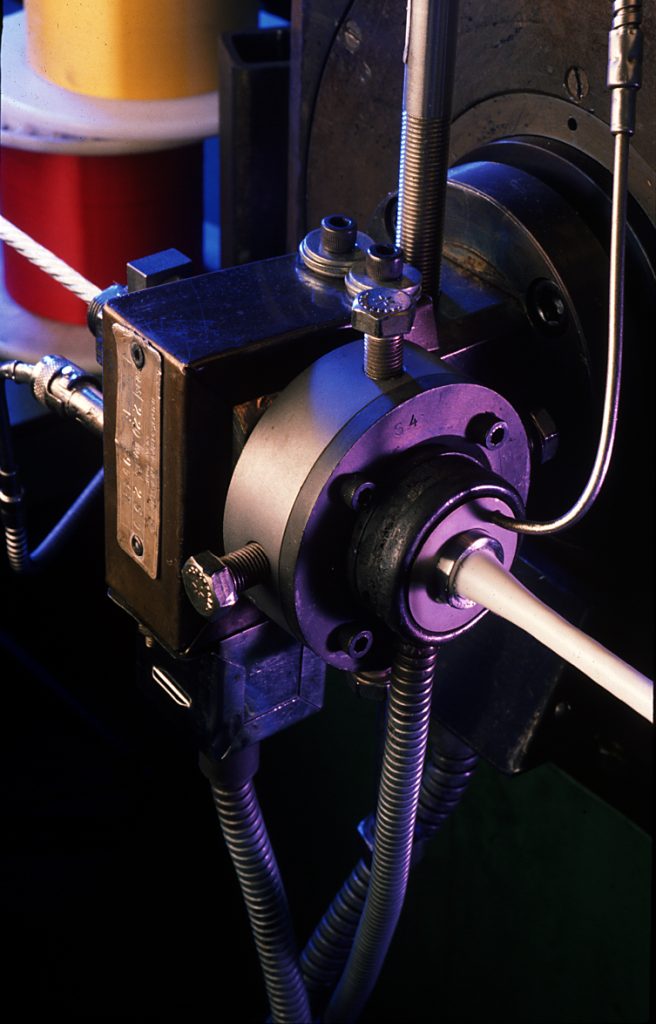

Extruded Plastic Insulation

Extruded plastic insulations usually create more build to the Litz conductor, but have higher dielectric strength and can be extruded in a range of wall thicknesses to meet a wider range of voltage requirements.

Extruded Litz constructions can also provide the opportunity to interweave the primary and secondary windings, and can therefore reduce the overall winding size. In addition, extruded plastic insulations tend to be more rugged and chemically resistant, can withstand higher temperatures.

| Extruded Insulation | Maximum Temperature | Common Use | Advantages |

|---|---|---|---|

| ETFE | 155° C | - Thin wall winding wire - Primary in multi-conductor - High frequency interconnect | - Good winding characteristics - Better at tight bend than other fluoropolymers - Excellent heat resistance - Excellent water/chemical resistance |

| FEP | 200° C | - Thin wall winding wire - High frequency interconnect - Primary in multi-conductor | - Excellent heat resistance - Outstanding water/chemical resistance - Outstanding flame retardancy - Low outgas |

| PFA | 250° C | - Thin wall winding wire - High frequency interconnect - Primary in multi-conductor | - Excellent heat resistance - Outstanding water/chemical resistance - Outstanding flame retardancy - Low outgas |

| PEEK/PAEK | 260° C | - High frequency interconnect - Winding wire | - Excellent dielectric properties, including PD resistance - Excellent chemical and abrasion resistance - Halogen free |

| PE/PP | 75° C | - Litz Coax / Twinax | - Very good dielectric properties - Outstanding water resistance |

| PVC | 105° C | - Winding wire - High frequency interconnect - Primary in multi-conductor | - Least expensive - Excellent flame resistance - Excellent flexibility - Medical grades |

| Polyurethane | 90° C - 105° C | - High frequency interconnect | - Excellent abrasion resistance - Very good flexibility - Can be coiled - Halogen free |

| Polyester | 90° C - 125° C | - High frequency Interconnect - Thin wall winding wire | - Excellent abrasion resistance - Can be coiled - Excellent flex life characteristics - Halogen free |

| TPE | 90° C - 125° C | - High frequency interconnect | - Highly flexible grades - Medical grades - Light weight grades - Hal free FR grades |

| Silicone | 200° C | - High frequency interconnect - High voltage interconnect | - Outstanding flexibility - Outstanding heat resistance - Medical grades - Can be coiled |